Design

Our team is experienced in mechanical and electrical engineering with the knowledge of CAD and stress analysis. We have a range of design skills to support both our own products and those of our customers, including the ability to reverse engineer existing designs. Our engineers also develop new designs to support many of our clients who then take these designs forward to manufacture.

Concept

Focused on cost and processes optimization, we create innovative solutions even when faced with the most complex challenges.

Rapid Prototyping

Enabling our partners to swiftly iterate and test design concepts, expediting the development process and facilitating innovation.

Certificate & Testing Support

Assistance in developing test plans and reports. Tailored support for specific certification programs.

Regulatory & Technical Consulting

In-depth consultation on EASA Part 21 regulations. Assistance with design certification and quality systems implementation.

Manufacturing

Our manufacturing services for aircraft interiors include the production of brackets, lease plates, composite partitions, bulkheads, and more. We prioritize precision and quality to deliver reliable and durable components that meet the stringent standards of the aviation industry.

Prototyping

3d printed, silicone molded, milled, bonded prototypes and trial fit models from various materials.

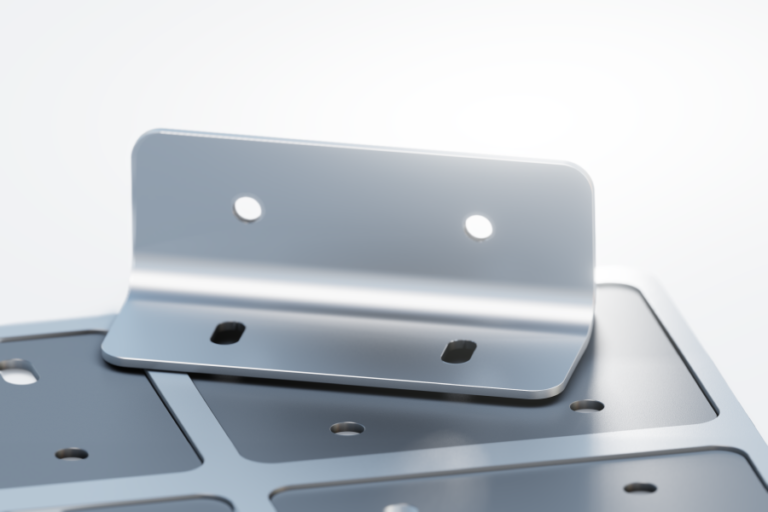

Sheet Metal Components

Emergency equipment brackets, lease plates, attachment brackets, trays and other parts / assemblies.

Composite Panel Structures

Partitions, dividers, base plates, shelf assemblies and other components.

Milled Components

Brackets, fittings, enclosures and other parts from aluminum, stainless steel and various other materials.

Wires & Harnesses

Custom wires and harnesses for ISPS, IFE, and all cabin wiring needs, with various materials, terminations, and insulation options.

Finishing

Various finishing options such as sanding, painting, polishing.

Assembly

Various assembly operations including riveting and bonding.

OEM Parts Sourcing & Kitting Solutions

We source OEM and aftermarket parts, manage logistics, and assemble ready-to-install kits—combining manufactured components, sourced parts, and all necessary hardware.